Conformal Coatings

MicroCoat Technologies

MicroCoat Technologies, a coatings, and adhesives development company was formed in 1996 by Sam Forman a veteran of over 60 years in polymer and thick film materials. He is a Founding and Charter Member, Fellow of the Society and Life Member of IMAPS, and also the recipient of the IMAPS Lifetime Achievement and Daniel C. Hughes awards

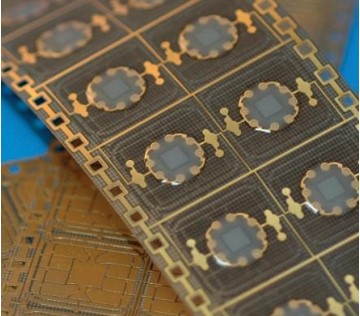

The Company specializes in advanced conductive, non-conductive, and UV cure adhesives and coatings formulations for the electronics, microelectronics, and semiconductor industries that supply products to the Aerospace, Defense, Medical, Opto-electronics, Telecommunications, Down-hole, and also the commercial sector of assemblies

The Company specializes in advanced conductive, non-conductive, and UV cure adhesives and coatings formulations for the electronics, microelectronics, and semiconductor industries that supply products to the Aerospace, Defense, Medical, Opto-electronics, Telecommunications, Down-hole, and also the commercial sector of assemblies

With over 150 combined years of polymer expertise, MicroCoat has developed unquestionably the finest fine-line no-bleed conductive adhesives and "sintered" silver adhesives with a TC of >150W/mK. Our nonconductive sealing adhesives have passed MSL1 testing for many companies. The Company ships several thousand syringes each month of conductive and non-conductive die attach adhesives, globtop, dam, and fill formulations for semiconductor assemblies and MCM's worldwide. MicroCoat's "B" staged conductive and non-conductive films and liquids are used extensively for both die attach and package sealing

HIGH TEMPERATURE, THERMALLY STABLE, POTTING APPLICATIONS

MCT 34T71ND-2 v.072720.06

A Single Component, Toughened, Microelectronic Grade Package Sealant with a Service Temperature of <-55 oC to Over >300°C and Meets NASA Low Outgassing Specifications

MicroCoat MCT 34T71ND-2 features a unique blend of performance properties including both high shear and peel strengths along with convenient handling and high/low temp properties allowing it to be easily rated MSL1. This extremely low moisture absorption adhesive has passed >1 year at 30oC/85%RH and can be used in MSL1 packaging. A Military and Medical Microelectronic sealing adhesive, MCT 34T71ND-2 is a 100% solids one part nonconductive thermosetting conductive adhesive designed primarily for sealing packages with mismatched thermal expansions in Military, Medical, “down-hole” hybrids, optoelectronics, automotive sensors, and all LCP packages, etc. Medical Application: There are no ingredients present in this formulation that has caused a failure in cytotoxicity or USP VI testing in any previous evaluations. ISO 13485 does not exclude materials unless the company specifically designs it to in which case we would need to know more about the design of your quality system. A much improved higher temperature resistant material. This is a one-component system formulated to cure at elevated temperatures that will withstand 85/85 for >3500 hours

MCT 34T71ND-2 has several outstanding processing advantages:

- No mixing is necessary before use

- This material is “Pre-mixed and Frozen”

- The viscosity remains constant with time (i.e. it will not thicken over time)

- Working life is unlimited* at room temperature, and the material is room temperature storable* for 1 month

- No cleanup required in-between shifts

OPTICALLY CLEAR GLOB TOPS

MCT 306-21

Clear Silicone Coating/Globtop

MCT 306-21 is a flexible, re-workable, non-conductive, silicone-based coating. The overall Ωbalance of peel strength, cohesion, and high temperature holding power provides a versatility that makes this product useful in a wide range of coating and bonding applications. This product is very resistant to flexing and creasing. Some applications for MCT 306-21 include, but are not limited to, coating for polyimide flexible circuits, polymer thick film circuitry, and semiconductor glob-top or MCM fill and attachments for stress-sensitive devices. 126-03 is one of the few non-conductive coatings that can bond/adhere to silicone substrates and surfaces. In addition, it can be bonded to some types of Teflon® surfaces and rubber surfaces. MCT 306-21 is optimized for syringe dispense, dipping, and spraying. The last two methods require some dilution

MCT 341014HTGT

A Single Component, Toughened, Microelectronic Grade Glob Top with a Service Temperature of <-65o C to Over >340°C and Meets NASA Low Outgassing Specifications

MCT 341014HTGT features a unique blend of performance properties including both high shear and peel strengths along with convenient handling and high/low temp properties. This is a one component system formulated to cure at elevated temperatures

341014HTGT has a number of outstanding processing advantages:

- No mixing is necessary prior to use

- This material is not “Pre-mixed and Frozen”

- The viscosity remains constant with time (i.e. it will not thicken over time)

- Working life is unlimited* at room temperature, and the material is room temperature storable* for 1 month

- No cleanup required in-between shifts

MICROELECTRONIC ENCAPSULANTS

High Throughput Solutions with High Reliability Low Stress Coatings As a global supplier of special adhesives, MicroCoat offers a range of UV and heat cure adhesives for Smart Card encapsulation and standard Glob Top/Chip-on-Board applications. We have developed these materials to maximize efficiency in production throughput with maximum reliability and total compatibility with MicroCoat Die Attach Adhesives

Types:

MCT UV Cure Dam & Fill Encapsulants Advantages

- Short cycle times, 10 - 60 sec

- Low ionic content

- UV curable, 320 - 405nm wavelength

- Good self-leveling characteristics

- Dam and fill adhesives create a homogeneous composition

MCT Heat Cure Dam & Fill Encapsulants Advantages

- Fast processing time and excellent dispensability

- High Tg level

- Low water absorption and good chemical resistance

- Fast cure time at moderate temperatures, 120°C-150°C

- Dam and fill adhesives create a homogeneous composition

Products:

MCT GTU1650

- UV cure one component epoxy resin

- High flexibility, low Tg

- Low ionic content

- Good environmental resistance

MCT GTUH1680

- UV and heat cure one component epoxy resin

- High Tg, low ionic content

- Low water absorption, good acid resistance

- Low coefficient of thermal expansion (α1)

MCT GTU1688

- UV cure one component epoxy resin

- Low water absorption, good chemical resistance

- Outstanding mechanical properties

- Low warpage, low coefficient of thermal expansion

MCT GTUH1671

- One component leadframe Dam material with good edge stability

- UV and heat cure at low temperature

- Low ionic content, low water absorption

- Good thermal conductivity

MCT GTH5071

- One component heat cure epoxy resin for Dam application

- Low water absorption, good chemical resistance

- Excellent thermal shock resistance

- Extremely high Tg

MCT GTH5088

- One component heat cure epoxy resin for fill application

- High processing efficiency

- Outstanding mechanical properties, when cured same performance as mold materials

- Low coefficient of thermal expansion ((α1)

UV CURE LOW TEMPERATURE GLASS REPLACEMENT FOR HYBRID CIRCUITS

MCT 3450-4B or G

UV Cure Epoxy Hybrid Circuit Protective Overcoat

MicroCoat Technologies 3450-4B or, G is a 100% solids UV cure epoxy protective overcoat for thick and thin film hybrid circuits. It is a screen printable protective coating with fast throughput, safety, and the environment in mind. Developed for overcoating very tightly trimmed thick or thin film resistors after trim so that there is no shift in resistor tolerance - NONE This chemical resistant epoxy formulation has been used to replace heat cure blue epoxy overcoats for hybrid circuits and chip resistors that require plating as well. The 3450-4 has a latent heat catalyst that cures the coating to a hard surface with the heat generated from the UV source. Good results have also been obtained using this material as a dielectric for polymer thick film resistor circuitry on PCB and flex materials. This material may be screen-printed on alumina, BeO, AlN, gold and palladium plated substrates including lead frames, standard thick film printed circuitry, or PCB substrates with excellent results. Its viscosity lends itself to self-leveling and may be adjusted for specific applications. The cured film is extremely tough, offers protection from thermal shock, moisture, abrasion, oxidation, and corrosion of certain conductive compositions, and may decrease the chance of silver migration in certain instances

CLASS VI MEDICAL COATING

Silver - Silver Chloride Inks

| Product | Ag/AgCl Ratio | Conductivity | Commonly Used | Comments |

|---|---|---|---|---|

| (ohm/sq/mil) | Cure Temps (°C) | |||

| 22-106-12 | 55:45 | 25 | 100 - 130 | Silver/Carbon/Silver Chloride, screen-printable |

| 22-113-09 | 82:18 | 0.05 | 100 - 160 | Extremely flexible, screen-printable |

| 22-115-02 | 80:20 | 0.10 | 100 - 120 | Flexographic printable |

| 22-117-23 | 70:30 | 0.05 | 100 - 160 | Extremely flexible, screen-printable |

| 22-117-43 | 85:15 | 0.08 | 100 - 150 | Waterbased, screen-printable |

| 22-119-10 | 95:5 | 0.05 | 100 - 175 | Pad-printable |

| 22-124-36 | 66:34 | 0.05 | 100 - 160 | Extremely flexible, screen-printable |

| 22-125-20 | 95:5 | 0.02 | 125 - 175 | Chemically resistant, epoxy based, screen-printable |

| 22-125-21 | 65:35 | 0.02 | 125 - 175 | Chemically resistant, epoxy based, screen-printable |