Advance Adhesive

MicroCoat Technologies

MicroCoat Technologies, a coatings, and adhesives development company was formed in 1996 by Sam Forman a veteran of over 60 years in polymer and thick film materials. He is a Founding and Charter Member, Fellow of the Society and Life Member of IMAPS, and also the recipient of the IMAPS Lifetime Achievement and Daniel C. Hughes awards

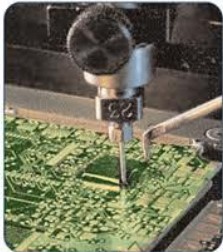

The Company specializes in advanced conductive, non-conductive, and UV cure adhesives and coatings formulations for the electronics, microelectronics, and semiconductor industries that supply products to the Aerospace, Defense, Medical, Opto-electronics, Telecommunications, Down-hole, and also the commercial sector of assemblies

The Company specializes in advanced conductive, non-conductive, and UV cure adhesives and coatings formulations for the electronics, microelectronics, and semiconductor industries that supply products to the Aerospace, Defense, Medical, Opto-electronics, Telecommunications, Down-hole, and also the commercial sector of assemblies.

With over 150 combined years of polymer expertise, MicroCoat has developed unquestionably the finest fine-line no-bleed conductive adhesives and "sintered" silver adhesives with a TC of >150W/mK. Our nonconductive sealing adhesives have passed MSL1 testing for many companies. The Company ships several thousand syringes each month of conductive and non-conductive die attach adhesives, globtop, dam, and fill formulations for semiconductor assemblies and MCM's worldwide. MicroCoat's "B" staged conductive and non-conductive films and liquids are used extensively for both die attach and package sealing

Conductive, Non-Conductive, and Thermally Conductive Die Attach Adhesives

In electronics, thermal management is crucial in both the design of circuit-board assemblies and in the production of semiconductor materials. For PC boards a crucial aspect can be the heating or cooling power required to keep a circuit within its specified operating temperature range. In the manufacturing of silicon wafers it is important to maintain a very uniform temperature distribution across the wafer in order to achieve quality production processes and high yields

- SMD Attach To PCB and Ceramic

- Screen Printing Traces

- Die Attach

- Solder Replacement

- Flex Silver Traces

- Flex Carbon Traces

- Anti-Static

- Chip Component Termination

- Tantalum Capacitor Termination

- Static Discharge

- Platable For SMD Components

- Quick-Set PCB Repair

- Bio-Sensors

- Silver Spray-On

CONDUCTIVE ADHESIVES

MCT SD0802-31DA

Extremely Low MSL *No Bleed Conductive Die Attach Adhesive

This extremely low moisture absorption adhesive, MCT SD0802-31DA has passed >1 year at 30°C/85%RH and should be able to be used in MSL1 packaging. This material also contains anti-bleed resin technology to prevent loss of resin system adhesion that is critical to wirebond and packaging performance. *MCT SD0802-31DA conductive adhesive will give you 8W/mK standard without sacrificing adhesion and very low outgassing per ASTM E595. This material is formulated to provide high cohesive energy, adhesive strength, stress absorbing for large die, and elongation at break. Short term at >300°C (2-3 minutes for Pb free reflow) if cured at 150°C for 60 minutes

MCT A795-VHT

Super High Temperature Conductive Die Attach Adhesive To >650°C

- Low Cure Temperature

- Semiconductor Die Attach with Molly Tab for “Down the Hole Hybrids” or attach to Headers Ag, Ni, Pd/Ag, Al, etc. (May not be direct bonded to Gold!)

- Silicon Die (No Gold on back) to power headers

- Platable For SMD Components

- Ceramic-to-Ceramic Heat Sink Bonding

- Substrate Attach to Nickel Plated Packages

For Vacuum Selaing Applications: All moisture is released between 300°C to 400°C. After that there is absolutely no outgassing. Prior to final brake at temperature there are <.01ppm H2O moisture given off. It appears from lab testing that if you cure the product for an additional 2 hours at 150°C (after 1-2hours at 120°C) this will eliminate any further moisture release

MCT 34-DH19/2 R3.3

High Temperature Electrically Conductive Adhesive

MCT 34-DH19/2 is an electrically conductive adhesive suitable for application by screen printing, dipping, and syringe dispensing and designed with high-temperature applications in mind. A high-temperature solution for attaching leads to ceramic substrates or too high-temperature thick film resistors Unlike conventional conductive materials, this product features a unique high continuous operation temperature and very high glass transition temperature making it especially well-suited for extreme conditions found near a furnace, heater, and for aerospace and down-hole applications. This product features excellent adhesion to a wide range of substrates such as Kapton, Mylar, ITO sputtered surfaces, glass, Al2O3, AlN, Gold, and a variety of other surfaces without the addition of treatment via acid or plasma etch. This product is very resistant to flexing and creasing and is suitable for very fine lines and spaces. Some applications for MCT 34-DH19/2 include, but are not limited to, EMI/RFI shielding of polyimide flexible circuits, polymer thick film circuitry, and membrane switches

MCT SD0802 Series

A High Performance Single Component, Very High Thermal Conductivity, Very Low Resistivity Conductive Epoxy Interposer for Connecting Silicon Stacked Die Layers

MicroCoat Technologies announces the arrival of their new low resistivity - high thermal conductivity die-stacking interconnect conductive adhesive MCT SD0802. Many companies that are manufacturing stacked flash devices have gone to very fine line dispensed conductive adhesive instead of wirebonding to make the connections from layer to layer. MCT has developed a magnificent solution. It can be a dispensed bead or using high speed jet dispensing of conductive adhesive, the material can be applied at 50 microns wide with no sag or slump to 16+ flash layers (tested to date) with a 7 day room temperature working life. Besides the cost and space savings compared to wirebonding the conductive paths provide a ground-breaking method for helping to cool the device(s) with the high thermal conductivity of the epoxy acting as cooling fins

It is shown that a 32MB 3D stacked DRAM cache can reduce the cycles per memory access of a twothreaded RMS benchmark on average by 13% and as much as 55% while increasing the peak temperature by a negligible 0.08ºC. Offdie BW and power are also reduced by 66% on average. It is also shown that a 3D floorplan of a high performance microprocessor can simultaneously reduce power 15% and increase performance 15% with a small 14ºC increase in peak temperature. Voltage scaling can reach neutral thermals with a simultaneous 34% power reduction and 8% performance improvement. Bryan Black, et al, Intel Corporation.

This adhesive is a thixotropic silver filled conductive frozen adhesive capable of dispensed line widths of 50 microns

CONDUCTIVE FLEXIBLE ADHESIVES

MCT 22-102-32

Flexible, High Temperature, Electrically Conductive Adhesive

22-102-32 is a flexible, electrically conductive, silicone pressure sensitive adhesive. The overall balance of peel strength, cohesion, lap shear strength and high temperature holding power provides a versatility that makes this product useful in a wide range of fastening and bonding applications. This product is very resistant to flexing and creasing. Some applications for 22-102-32 include, but are not limited to, EMI/RFI shielding of polyimide flexible circuits, polymer thick film circuitry, gaskets, and electrical attachments for stress sensitive devices. 22- 102-32 is one of the few conductive adhesives that can bond to silicone substrates and surfaces. In addition, it can be bonded to some types of Teflon® surfaces and clean aluminum and stainless steel as well

NON-CONDUCTIVE ADHESIVES

MCT 36190-2GT

A High Performance Single Component, Non Frozen Non-Conductive Epoxy For SMD and Die Attach With an Operating Temperature Range of -65°C to +240°C

MicroCoat 36190-2GT features a unique balance of high performance properties including both high shear and peel strengths along with convenient handling and high/low temp properties. This is a single component system formulated to cure at elevated temperatures. This is a one part thermosetting non-conductive epoxy designed primarily for die attaching semiconductors and surface mount devices in military, “down-the-hole” hybrids, optoelectronics, automotive sensors, transducers, etc. The material is a thixotropic paste which may be applied by screen printing or syringe. It is 100% solids, and posses' good handling and storage properties. This Al2O3 filled non-conductive die attach adhesive is designed to bond ICs and components to advanced substrates such as ceramic, PBGAs, CSPs, plated lead frames, and array packages. Hydrophobic and stable at high temperatures, the adhesive produces a void-free bond line with excellent interfacial adhesion strength to a wide variety of organic and metal surfaces including solder mask, BT, FR, polyimide, gold, Kapton and Mylar. This material is formulated to provide high cohesive energy, adhesive strength, and elongation at break

UV/IR CURED FLIPCHIP UNDERFILLS

MCT 9116-04CUFL

Extremely Thermally Conductive Flowable BGA Underfill

9116-04CUFL is a nitride filled, single component, frozen, epoxy compound for BGA and flip chip underfill applications with a TC of 2.88W/mK. This product is designed to release entrapped air rapidly during cure resulting in a smooth, pinhole free surface. The viscosity is such that this material will flow nicely under the component and around the solder or conductive epoxy balls. Adhesion to Si, GaS, GaN, glass, epoxy molded components, is excellent

CLASS VI MEDICAL ADHESIVES

MCT POLYMER ADHESIVE 423-06

Two Component Low Viscosity Epoxy System For High Performance Bonding, Sealing, Coating. Fast Set Up and Handling Time

MCT Polymer Adhesive 423-06 is a two component low viscosity epoxy resin system for high performance bonding, sealing, coating, as well as small encapsulations, potting and castings. It is formulated to cure readily at room temperature or more quickly at elevated temperatures. One notable property is its very fast curing at room temperature. It has a convenient 2 to 1 mix ratio by volume and contains no solvents or diluents. MCT Polymer System 423-06 produces high strength rigid bonds, which are remarkably resistant to chemicals including water, oil, many organic solvents, as well as cold sterilants, ETO and gamma radiation. It has a wide service temperature range of -60°F to + 250°F. It bonds well to a wide variety of substrates including metals, glass, ceramics, wood and many plastics. 423-06 has exceptionally low linear shrinkage upon cure. The cured compound is an outstanding electrical insulator. 423-06 low viscosity makes it excellent for thin line deposits. In addition, 423-06 will meet USP Class VI specifications but has not been tested as such

MCT Flexible Epoxy Sealing Adhesive 54 -177-1

Two Component Flexible Epoxy System for High Performance Bonding, Sealing, with a Fast Set Up and Handling Time

MCT Polymer Adhesive 54-177-1, a longer pot/gel time version of 54-144-1 is a two component high flow thixotropic epoxy resin system for a slightly flexible high performance bonding and sealing, as well as small encapsulations, potting and castings. It is formulated to cure readily at room temperature or more quickly at slightly elevated temperatures. One notable property is its very fast curing at room temperature. It has a convenient 2:1 mix ratio by volume and contains no solvents or diluents. MCT Polymer System 54-177-1 produces high strength bonds, which are remarkably resistant to chemicals including water, oil, and many organic solvents, as well as cold sterilants, ETO and gamma radiation. It has a wide service temperature range of -40°F to + 200°F. It bonds well to a wide variety of substrates including metals, glass, ceramics, and many plastics. 54-177-1 has exceptionally low linear shrinkage upon cure. In addition, 54-177-1 will meet USP Class VI specifications but has not been tested as such